For cozy warmth in the cold season

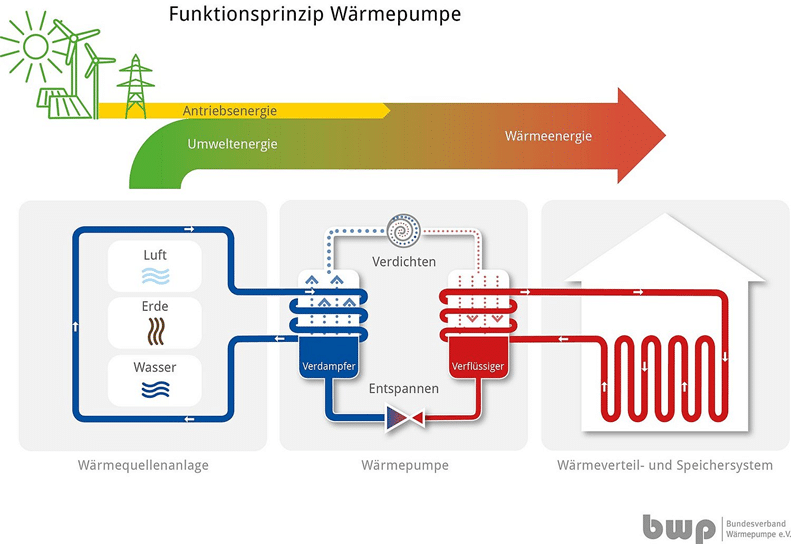

In simple terms, heat pumps are “reverse air conditioning systems” in which heat is absorbed from the ambient medium (air, water, earth) and cold is released. Incidentally, most air conditioning systems (which are in principle also heat pumps) can also be used for efficient heating (ideal especially in the transitional period).

The cleanliness and condition of the energy exchange surfaces (heat exchangers) are particularly important for the efficiency and cost-effectiveness of air/water heat pumps.

Therefore, the maintenance of heat pumps is particularly important before the heating period as these heat exchangers become increasingly dirty during operation. It is therefore important to service a heat pump in good time before the heating period.

Basically, 3 different heat sources can be used for a heat pump:

Each heat source has specific requirements and efficiency potential. The choice depends on the location, climatic conditions and local circumstances:

- Air source heat pump: Easy to install, but less efficient in cold temperatures

- Geothermal heat pump: Requires a borehole, but provides a constant heat source

- Water heat pump: Uses groundwater or surface water, but requires access to suitable water sources

The most important points for reliable and efficient heat pump operation

Several factors are crucial for the reliable and efficient operation of heat pumps. Here are the most important ones:

Correct dimensioning of the system

- The heat pump must be matched to the size of the building and the heating requirement (heating load). A pump that is too large or too small can operate inefficiently and increase energy consumption

High-quality installation

- Professional installation is crucial. The positioning of the heat pump and the correct integration into the heating system (e.g. underfloor heating) have a significant influence on efficiency

Heat source efficiency

- The efficiency depends heavily on the heat source used (air, water or ground) and the installation location:

- Air source heat pump: should be installed in areas with a milder climate or in sunny locations to achieve high energy efficiency

- Geothermal heat pump: Stable temperatures in the ground offer reliable and high efficiency in heating and cooling operation all year round

- Water heat pump: Requires reliable and temperature-stable water sources that are checked regularly. Feasibility often depends on local conditions/use restrictions (water protection)

Regular inspection and maintenance

- Heat pumps should be regularly inspected and maintained to ensure reliable operation

Optimum operating mode

- The flow temperature should be kept as low as possible, as heat pumps work more efficiently when the difference between the outside temperature and the target temperature is small

- Night setback and optimized control (e.g. via smart thermostats) can improve efficiency

Thermal insulation of the building

- Good building insulation is crucial for reducing heat demand and operating the heat pump efficiently. Uninsulated buildings lead to higher energy consumption, lower efficiency and greater strain on the heat pump

Power supply

- Heat pumps require electricity to operate. The use of green electricity or in combination with a photovoltaic system increases environmental friendliness and economic efficiency

- The installation of heat pumps significantly increases electricity consumption – the current market prices should be checked regularly (at least once a year) (e.g. via the E-Control tariff comparison portal ) and, if necessary, switched to a cheaper energy supplier

System integration

- Heat pumps work efficiently when they are integrated into a holistic heating system that is tailored to the building. This also includes integration into existing hot water systems and, if necessary, a combination with other heating sources such as solar thermal energy

- It is also possible (and often makes more sense) to use separate heat pumps for building heating and hot water heating (or to heat the hot water with a heating rod in summer if a PV system is available) – this extends the service life of the “large” heating heat pump as it can be switched off during the non-heating period

Ambient temperature

- The ambient temperature is particularly important for air source heat pumps, as low temperatures impair the efficiency of the pump. However, modern heat pumps are designed for operation even at temperatures below freezing point

- From an outdoor temperature of just above 0°C, the outdoor unit can ice up – this icing is carried out automatically by the appliance, but the heat output to the building is interrupted during this time and the efficiency drops noticeably

Funding programs and regulations

- In many countries, there are subsidy programs that support the use of heat pumps. It is important to find out about applicable regulations and funding opportunities in order to reduce costs

A well-maintained system that is tailored to the individual needs of the building and location ensures reliable and efficient long-term operation of the heat pump.

Legal requirements for the installation of heat pumps

In Austria, there are a number of legal requirements and regulations that must be observed when planning and installing heat pumps. These relate to the installation as well as the operation and approval of systems. Here are the most important points:

Approval of the construction:

- Air source heat pumps: In many Austrian federal states, no planning permission is required for the installation of an air source heat pump as long as certain noise protection requirements and distance rules are complied with. However, if the heat pump is installed in a particularly sensitive environment (e.g. nature reserve), a permit may be required

- Geothermal heat pumps (geothermal energy): For geothermal heat pumps that use deep geothermal probes, a borehole usually requires a permit. This requires a permit from the local water authority, as deeper boreholes can affect the groundwater

- Water heat pumps: If groundwater is used for a water heat pump, a permit is also required. This applies in particular to the extraction and reintroduction of water into the groundwater

Distance regulations

- For air source heat pumps in particular, there are specifications regarding the minimum distance to the property boundary and to neighbors’ buildings in order to avoid noise pollution. These regulations can vary depending on the federal state and municipality, but a distance of around 3 to 5 meters is often required

3 to 5 meters is often required

Noise protection regulations

- Air source heat pumps must comply with noise protection regulations, especially in residential areas. There are legal requirements for the maximum permissible noise emission, especially at night. It is therefore important to choose the location of the heat pump carefully or to take noise protection measures

Environmental protection requirements

- When using geothermal energy or water as a heat source, environmental protection regulations must be observed. These include the protection of groundwater and soil. Therefore, frequent hydrogeological investigations are required before installing a geothermal heat pump to ensure that the groundwater is not affected

Energy certificate

- For new buildings or major renovations, the issue of an energy performance certificate is confirmed, which also assesses the efficiency of the heating system, such as the heat pump. This energy certificate is necessary to check whether the building meets the legal requirements for energy efficiency

Technical standards and regulations

- Heat pumps must comply with the technical standards applicable in Austria. These include standards for the installation, operation and safety of the system. The standards for electrical installations (e.g. ÖVE EN 50110, E 8001, E 8701) and refrigeration technology (ÖNORM EN 378-1, H 6151) are particularly important here

- The EU regulations, in particular the Ecodesign Directive, are also binding in Austria. This directive specifies requirements for the energy efficiency of heat pumps

Water law permit

- When using groundwater or surface water (e.g. for water heat pumps), a water permit is required in accordance with the Austrian Water Act (WRG). This permit regulates the withdrawal and reintroduction of water.

Grid connection and electricity tariffs

- As heat pumps are powered by electricity, a grid connection must be made with the relevant electricity supplier. In some cases, grid operators may impose technical requirements on the electricity connection of the heat pump in order to ensure grid stability.

- Heat pumps can often be operated with special heat pump electricity tariffs that offer favorable conditions.

The legal requirements for the operation of heat pumps in Austria depend on the type of heat pump and the local conditions. It is particularly important to comply with noise protection regulations, to ensure that ground or water sources are used in an environmentally friendly manner and to observe building regulations and any necessary permits. It is advisable to seek comprehensive advice before installing a heat pump and to find out about regional differences and funding opportunities

Legal requirements for the operation of heat pumps

In Austria, there are various test regulations for heat pumps that relate to environmental aspects (water law, groundwater protection), the tightness of refrigerants, noise emissions and technical safety regulations. Water law tests are particularly important for geothermal and water heat pumps. Although regular maintenance and inspections are not required by law in some cases, they are essential for reliable and efficient operation

Inspection obligations for water heat pumps

- Water law inspection: The use of groundwater or surface water as a heat source requires a water law permit. This permit is issued by the competent water authority and regular inspections and monitoring obligations may be prescribed to ensure that the water is not excessively extracted or polluted.

Testing of refrigerant systems

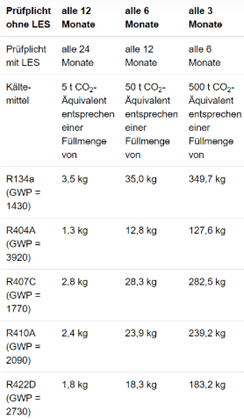

- Heat pumps that work with refrigerants (as is the case with almost all systems) are subject to the provisions of the EU Regulation on fluorinated greenhouse gases (F-Gas Regulation 517/2014 – in force since 1.1.2015).

This prescribes regular leak tests and depends on the type and quantity of refrigerant (CO2 equivalent) (can be found on the type plate of the system).

- Inspection intervals:

- Systems with a CO₂ equivalent of 5 to 50 tons must be tested every 12 months.

- Systems with a CO₂ equivalent of 50 to 500 tons must be tested every 6 months.

- Systems with a CO₂ equivalent of over 500 tons must be checked every 3 months.

- Systems with an automatic leakage detection system (LES) can double the inspection intervals.

- All tests must be documented in the test logbook

- Safety tests are required by the Refrigeration Systems Ordinance (KAV) from a refrigerant charge weight of more than 1.5 kg – test interval is required once a year by a certified refrigeration system technician, entry in the test logbook is mandatory

Maintenance and inspection

- Maintenance contracts: Many heat pump manufacturers offer or require regular maintenance to ensure the efficiency of the system and extend its lifespan. While these maintenance obligations are not required by law, they may be necessary in certain cases (e.g. for subsidies or guarantees).

- Inspections in accordance with safety regulations: larger commercial systems are subject to general operating safety regulations, which require regular inspections and tests of the system.

Who is authorized to carry out inspections and maintenance on heat pumps?

The testing of heat pumps in Austria may only be carried out by qualified specialists such as heating engineers, refrigeration engineers and electricians.

For specific tests, such as the leak test for refrigerants, additional certification in accordance with the F-Gas Regulation is required.

Here are the relevant professional groups and qualifications that are authorized to test or maintain heat pumps:

Plumbers and specialist companies for heating, air conditioning and ventilation

- Specialist companies in the heating, air conditioning, ventilation and sanitation (HVAC) sector are generally the qualified companies that are authorized to install, maintain and test heat pumps. These companies have specially trained technicians who are familiar with the technical requirements and legal regulations

- It is particularly important that the installer or company has a trade license for the heating technology sector

Refrigeration technician

- As heat pumps use refrigerants, a refrigeration technician qualification (“refrigerant certificate”) is required to carry out work on the refrigerant circuits. Refrigeration technicians are authorized to carry out leak tests on systems and work on the refrigerant circuit, for example, as stipulated in the EU F-Gas Regulation

- These technicians must have completed special training for handling fluorinated greenhouse gases (F-gases) in order to be allowed to replace refrigerants or carry out leak tests

Electricians

- As heat pumps are operated electrically, companies require electricians to carry out regular electrical tests on the system. This primarily concerns the safety of the electrical connections and components of the heat pump

- Electricians who are qualified to inspect and maintain electrical installations must have a trade license in the field of electrical engineering

Certified test centers

- In some cases, especially for larger or commercial systems, certified inspection bodies can be called in to carry out legally required inspections. This applies, for example, to the inspection of water law requirements for geothermal or water heat pumps or regular noise measurements

Experts

- Experts (usually in cooperation with authorities or insurance companies) can also carry out inspections in certain cases. This is particularly the case when it comes to compliance with environmental regulations (e.g. groundwater protection) or operational safety regulations

- Experts are also active in the preparation of expert opinions for funding applications or in disputes relating to the function and efficiency of heat pumps

Authorizations under the F-Gas Regulation

- Companies and technicians who carry out work on the refrigerant circuits of heat pumps must be certified in accordance with EU Regulation No. 517/2014 on fluorinated greenhouse gases (F-Gas Regulation). This authorization is acquired through training courses offered by accredited training institutions. Without this certification, no work may be carried out on systems containing fluorinated gases

Maintenance contract with the manufacturer

- Many heat pump manufacturers offer maintenance contracts that ensure that the systems are regularly checked and serviced by authorized technicians from the manufacturer. These technicians are specially trained for the respective system and are familiar with the manufacturer’s specific requirements

Important qualifications:

- Heating technology and refrigeration technology training

- Trade license for heating, ventilation and air conditioning (HVAC) or electrical engineering

- Certification in accordance with the F-Gas Regulation for work on refrigerants

- Specialist knowledge of geothermal energy for geothermal heat pumps

What consequences can a lack of maintenance have?

A lack of heat pump maintenance can have a significant negative impact on the reliability, service life, safety and performance of the system. Here are the most important consequences:

A lack of or inadequate maintenance of heat pumps can have numerous negative effects on the performance, the service life of the system and even on the environment.

Here are the most important consequences that can result from a lack of maintenance:

Reduced efficiency

- Loss of performance: Without regular maintenance, the efficiency of the heat pump can drop considerably. Deposits or dirt on the heat transfer surfaces mean that the heat pump requires more energy to achieve the same output (efficiency decreases)

- Increased power consumption: If components such as the evaporator or condenser are not cleaned regularly, the system has to work harder, which leads to increased power consumption and therefore higher operating costs

Higher operating costs

- Poor maintenance results in the heat pump operating inefficiently and consuming more energy. This leads directly to higher energy costs for the operator

- In addition, small problems, if not detected in time, can lead to major damage requiring costly repairs or replacement of parts

Shorter service life of the system

- Without regular maintenance, important components such as the compressor or heat exchangers can wear out regularly. These parts are particularly cost-intensive and premature failure can significantly shorten the service life of the entire heat pump

- A well-maintained heat pump can achieve a service life of up to 20 years. This time can be significantly shortened if maintenance is not carried out properly

Increased probability of default

- The probability of technical faults or total failure of the heat pump increases without regular maintenance. The compressor, the refrigerant circulation system and the electronic controls are particularly susceptible in this respect

- A breakdown in the cold season can not only lead to inconvenience, but also cause additional costs due to emergency service calls and alternative heating solutions

Problems with refrigerants

- Leaks in the refrigerant circuit can occur if the heat pump is not regularly checked for leaks. Refrigerants, especially fluorinated greenhouse gases (F-gases), are harmful to the environment and are subject to stricter regulation by the EU. Leaking refrigerant can lead to inefficient operation or total failure and cause environmental damage

- In this case, a legally prescribed leak test is often not complied with, which can have legal consequences and possible fines

Deteriorated heating performance

- If filters, valves or other parts are clogged or dirty, the heat pump can no longer provide its full heating capacity. This means that rooms cannot be heated sufficiently, especially in the cold season

- With air source heat pumps, soiling of the outdoor air heat exchanger can lead to significantly reduced heat absorption from the ambient air

Increased noise development

- Heat pumps that are not regularly maintained can be purged. Wear on moving parts such as fans or compressors or imbalances can lead to increased noise. This is a particularly common problem with air source heat pumps and can cause a nuisance to the surrounding area

Legal and warranty issues

- Many manufacturers require regular maintenance of the system in order to maintain warranty claims. Without the prescribed maintenance work, the warranty claim may be invalidated and you will have to pay for repairs or spare parts out of your own pocket

- In the case of commercial systems, problems with operational safety regulations can also arise if maintenance is neglected

Environmental damage

- A poorly maintained heat pump can be harmful to the environment, particularly through refrigerant leakage or inefficient energy consumption. Fluorinated greenhouse gases contribute to climate change, and inefficiently operated heat pumps have a higher carbon footprint as they require more electricity

Cost-intensive repairs

- Small technical defects, such as leaking seals or clogged filters, can go unnoticed without maintenance and develop into major problems. This often leads to costly follow-up repairs or the replacement of key components such as the compressor, which could have been avoided with earlier maintenance

Regular maintenance (especially before the heating season in autumn) is therefore crucial to ensure efficiency and safety and to maximize the efficiency and service life of the system.

As you can see, correct maintenance and testing is essential for the reliability and efficiency of systems. Our MyBuilding24 app helps you to keep track of all maintenance work easily and reliably so that you don’t overlook this important maintenance and reminds you in good time when it needs to be carried out.

If you want to keep your properties, systems, machines and equipment in top condition and have your inspection and maintenance obligations under control, then use our

mybuilding24 APP or follow this link and register today – https://mybuilding24.com/de/ – to keep your building running economically and reliably for a long time to come.