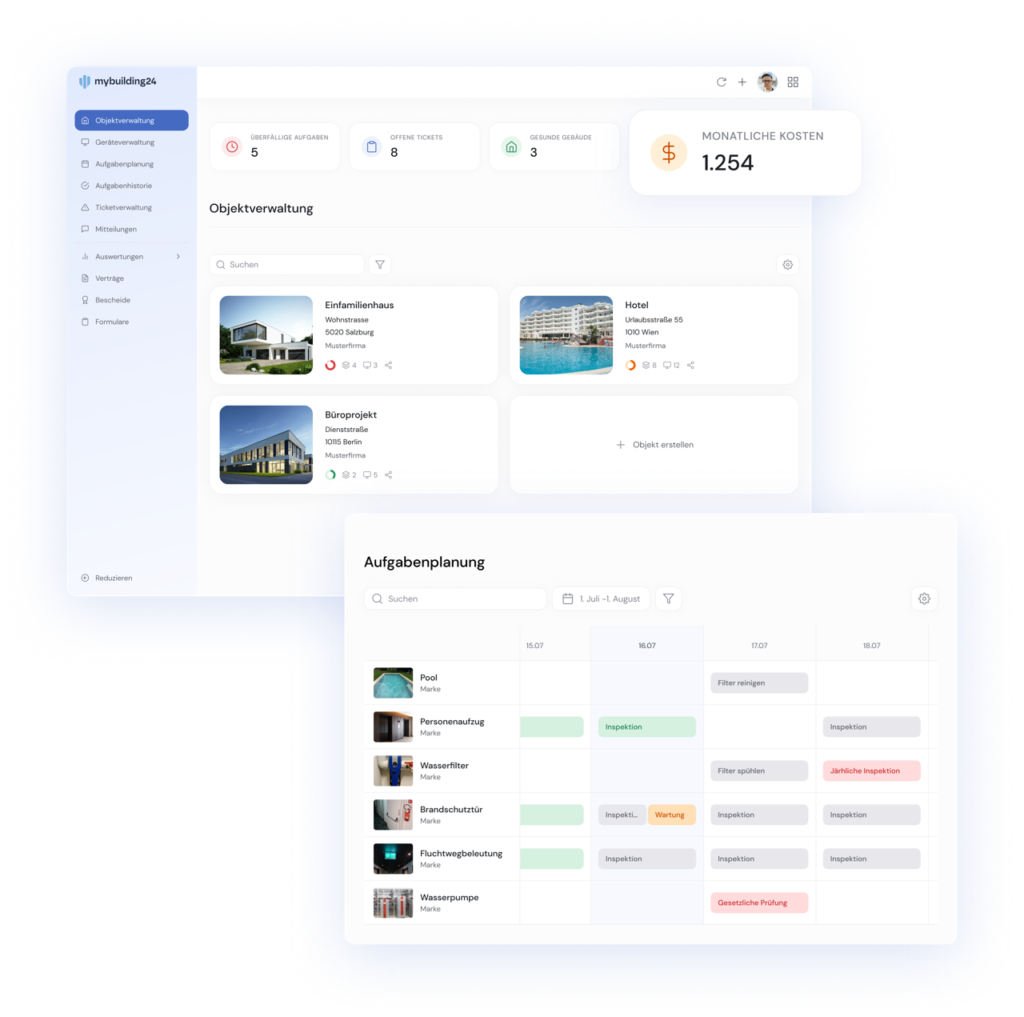

- mybuilding24® for industrial companies

Maintenance software for industrial companies

As an experienced developer of maintenance software, we know the challenges faced by decision-makers in industrial companies.

mybuilding24® offers the optimal solution to improve your maintenance management and ensure smooth operations.

200+ customers already rely on efficient & digital maintenance with mybuilding24®.

- mybuilding24®

Advantages for industrial companies

Comprehensive maintenance planning

Create detailed maintenance plans, assign tasks and keep track of upcoming work.

Automated reminders

Never miss an important maintenance appointment again. Our software automatically reminds you of upcoming tasks.

Efficient resource management

Plan the deployment of personnel and materials in order to optimally coordinate maintenance work and avoid bottlenecks.

Documentation and reporting

Record maintenance logs, checklists and notes digitally. Create detailed reports for transparency and traceability.

Mobile support

Access your maintenance data from anywhere and at any time. Track the completion of tasks and their progress directly from your mobile device.

Reliability

Correct and regular maintenance can reduce downtime, avoid stoppages and prevent idle time.

01

Maintenance software for industrial companies

mybuilding24® offers a cost-effective solution for industrial companies of various sizes.

With an intuitive user interface and simple implementation, the software adapts seamlessly to existing operating processes and requires no extensive training.

This means that entire production systems, including test intervals, can be created.

02

Maintenance software for growing and large industrial companies

For larger industrial companies, mybuilding24® offers scalable and flexible solutions.

The software supports preventive maintenance, inspections and servicing work and can be easily adapted to your specific requirements.

- Advantages of mybuilding24

Optimize your maintenance processes

without mybuilding24

- Higher costs

Inefficient processes lead to higher expenses

- Lost time

Manual documentation is time-consuming and error-prone

- Lack of overview

Maintenance data is scattered and difficult to access

- Higher energy consumption

Non-maintained devices often require more resources

- Liability risk

No insurance cover if maintenance is not carried out

- Shortened service life

Non-maintained devices often have a shorter service life

- Health risk

Failure to maintain appliances regularly can result in a health risk

- Lack of resources

The limited technical staff are working at maximum capacity

with mybuilding24

- Cost reduction

Automated processes minimize expenses

- Time saving

Digital documentation simplifies maintenance tracking

- Transparency

All maintenance data accessible in one central location for external and internal users

- Energy efficiency

Regularly evaluated appliances require less energy.

- Minimization of liability risk

Regular maintenance reduces the risk of liability issues

- Longer running time

Regular maintenance can significantly increase the service life of devices

- Health

Regular filter changes for ventilation systems, etc.

- Resource efficiency

Efficient device maintenance that takes the strain off staff

- Made in Austria

Maintenance in the 21st century

efficient.

legally compliant.

digital.

At mybuilding24® we stand for quality from Austria.

Our focus is on creating a legally compliant and simple way to handle the maintenance of equipment professionally and digitally.

- Get started with mybuilding24®

Discover mybuilding24®

Get started with our software now for free or book a demo with one of our experts.

200+ trust in mybuilding24®

- FAQ

Frequently asked questions

Maintenance and servicing software optimizes the efficiency of machines and systems, minimizes production downtime, extends the service life of equipment and improves overall performance.

Choosing the right maintenance software requires consideration of the specific needs of the industrial company, such as customizability, asset management, reporting and integration with existing systems.

Functions such as maintenance planning, digital inventory, preventive maintenance options, failure prevention, reporting and analysis are essential for industrial companies.

The costs for implementation vary depending on the software provider, scope of functions and size of the industrial company.

Yes, maintenance software can help minimize downtime in production by enabling preventive maintenance schedules, efficiently planning maintenance work and providing timely alerts for necessary maintenance actions.

Preventive maintenance is crucial to avoid breakdowns.

The software enables precise planning, continuous monitoring, recording of maintenance histories and analysis of data for predictive maintenance decisions.